kleinkraft: Small but mighty energy pioneers

February 6, 2024|TA

The world is racing to transition from fossil fuels towards more renewable energies. On energy storage, kleinkraft is blazing a new trail.

kleinkraft is actively driving research into energy efficiency, renewable energies, and how to use CO2 for the synthesis of chemicals. They are on a mission to transform the decarbonisation landscape: the outcome of their chemical processes enables efficient and sustainable production of batteries, plastics and materials whose production is otherwise anything but environmentally friendly.

Not content with purely expanding scientific knowledge, they also help companies profit from energy transition by providing technical knowledge about energy efficiency, renewable energies, and how to obtain public funding for projects. These measures help companies not only to reduce energy costs, they are the foundation to meet constantly rising sustainability requirements.

The early days

Since its founding in 2015, the powerhouse behind kleinkraft has been founder Magdalena Teufner-Kabas. Up until the summer of 2017, she also worked at the Austrian Institute of Technology (AIT) exploring the use of CO2.

Immediately after kleinkraft was founded, it began making waves. Large companies were impressed by the smaller firm’s expertise and in its first year alone kleinkraft carried out external energy audits at multiple large companies. They get to know and optimize the energy processes of manufacturing companies – both large and small – in great detail and work with innovative and exceptional personalities who, thanks to kleinkraft’s meticulous strategies and planning, take meaningful action on their projects.

But the company had bigger dreams than just consulting and today their work is incredibly varied.

By partnering with Teufner-Kabas’ husband, Mr Kabas, the company was able to build scalable projects in the field of renewable energies and energy efficiency, and on international feasibility studies and public funding. Together, the couple re-founded kleinkraft OG in August 2018. Now, their research focuses on turning CO2 and alcohol into organic carbonates (such as diethyl carbonate). These carbonates can be used in the production of batteries and plastics, for example.

A plan to help foster the energy transition

Smart, sustainable energy solutions are more needed than ever, as the current rate of energy transition will not be sufficient to meet the 1.5°C warming limit set out in the 2015 Paris Agreement. Additional measures for the capture and use of CO2 are increasingly necessary, and there is no time to waste.

kleinkraft has one solution. Whilst CO2 is a leading cause of climate change, it can also be used as a source of raw materials for the production of chemicals. Together with the TU (Technical University Vienna) and implementation partners, kleinkraft is concentrating on developing an efficient process for using CO2 as a carbon source for industry. The funding received from the Vienna Business Agency and the FFG (Austrian Research Promotion Agency) puts them firmly on track to establish their pilot plant and make significant strides in the production of organic carbonates from CO2.

“Our work would not have been possible without the financial support of the Vienna Business Agency.”

Magdalena Teufner-Kabas

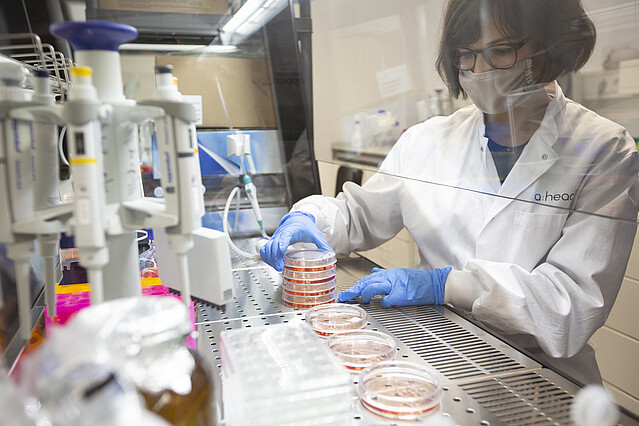

They have managed to develop a laboratory process useable in industrial companies which involves using membranes to remove by-products (namely, water) from the catalytic conversion process within a pressure chamber. Figuring it out was a long process, but Teufner-Kabas and her team persevered and the determination paid off.

Thanks to the modular design, scaling is vastly simplified and, crucially, the economic efficiency of whole operation is greatly improved.

In recognition for her pioneering efforts in the environmental field, Teufner-Kabas was awarded the Environmental Prize by the Austrian Society for Environment and Technology (ÖGUT) in 2023.

Looking to the future

Austrians hotly debate whether CO2 should be captured out of power plants and injected into underground storage facilities. Teufner-Kabas is opposed, on the basis that it won’t actually solve the problem, but rather pass it on to the next generation.

Her solution is to minimize emissions in the first place. A comparative life cycle analysis of the production of diethyl carbonate revealed that Teufner-Kabsas’ CO2 process with alcohol produces on average only 44% of the emissions generated by the conventional process.

In other words, the kleinkraft process is a seriously viable option in the crusade against carbon dioxide. As it is, talks are in progress with potential industrial companies for implementation.

Teufner-Kabas acknowledges that achieving decarbonisation goals isn’t always easy, but is optimistic that the research and development in this sector is advancing. The best way to reach climate goals is to implement climate protection projects far more swiftly and in fact, she claims, companies are often further ahead of the game than politicians give them credit for.

kleinkraft has every reason to be proud of the progress and be optimistic about their vision for the future. They are no longer just researching how to use CO2, but are already manufacturing products from it – a big step forward. Another highlight will be starting operations at a pilot plant with a potential project partner, and working on improving the safety submissions and the production of further organic carbonates. And as if this wasn’t enough to keep them busier than ever, a larger plant is also in the works.

kleinkraft

Services of the Vienna Business Agency

Funded through the Initiating Cooperations programme in 2018 and 2020

Funded through the From Science to Products programme in 2019

Innovation Funding